Application of the Product: Water Transfer Pump

In the heart of rural landscapes, the significance of efficient water transfer solutions cannot be overstated. Our Water Transfer Pump stands as a beacon, addressing vital challenges faced by a customer navigating water delivery in remote areas. For communities reliant on agriculture, this pump becomes more than a tool; it’s a lifeline.

In this case study, we unravel the challenges encountered by our customers and showcase how the Thornado pump, designed for reliability and affordability, emerged as the cornerstone of seamless water delivery. Join us in the journey of empowering rural areas with a robust and efficient water transfer solution.

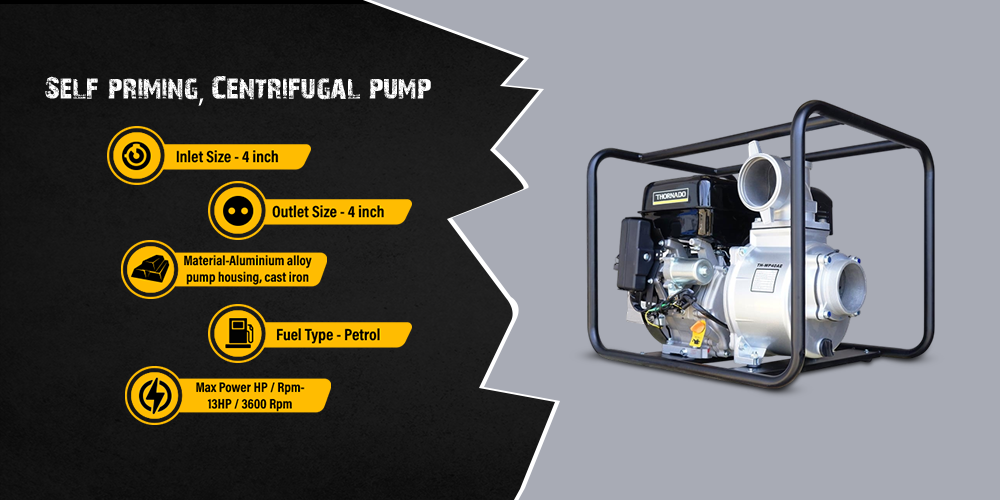

Equipment Supplied: 4-inch high-flow petrol water pump

Location of the Customer: Rural/Remote Area

Challenges Faced:

- Heavy reliance on the pump for crucial business operations.

- Delivery of water to customers in the town.

- Need for a high-quality pump without a hefty price tag.

- The requirement to fill up the water cart tank swiftly and efficiently.

Solution:

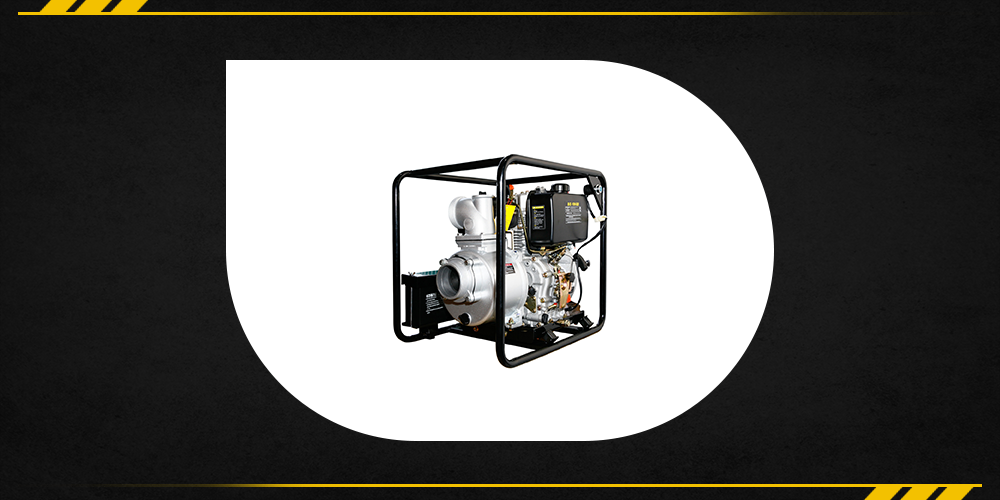

In response to the multifaceted challenges, we provided a Thornado 4-inch petrol water pump, addressing concerns about engine start-up in case of a flat battery. Opting for a petrol engine proved advantageous, given its relatively lighter weight and the availability of spare parts, contributing to enhanced reliability.

Key Features of Thornado 4 Inch Petrol Water Transfer Pump:

Here are a few capabilities of the Thornado 4 Inch Petrol Water Transfer Pump as you explore its key features-

High-Performance Engine:

- True commercial 13HP 389cc 4 Stroke OHV engine.

- EPA-III emission certified, reducing carbon footprint.

Impressive Specifications:

- Max heads of 30 meters for efficient water displacement.

- Max flows up to 90,000 litres per hour for swift operations.

- 4-inch suction/discharge ports ensuring substantial water movement.

Versatile Suction Depth:

- Capable of drawing water up to 7 meters in height, enhancing adaptability and widening the scope of application.

Advanced Safety Features:

- Anti-vibration design for stability during operation.

- High-quality mechanical seal for durability.

- Low oil alert sensor prevents engine damage by shutting down when oil levels drop.

Rigid Construction:

- Rigid Mounted Cast Iron Volute and Cast Iron Impeller for enduring performance.

- Heavy-Duty Full Frame Protection ensures longevity.

Implementation of the Petrol Water Transfer Pump:

To ensure optimal pump performance, we included a 5m suction hose with a foot valve and camlock connections. Additionally, we integrated a one-way valve at the pump output and a pressure relief valve in the tank, facilitating efficient water recirculation.

Results and Benefits:

The customer expressed satisfaction with the pump unit and even ordered a spare as a precaution. The pump consistently delivered exceptional performance, prompting recommendations within the industry. The success story inspired other businesses having operations related to the water cart to adopt our pump for their operations.

Challenges Overcome and Lessons Learned:

- Regular pump inspections are crucial to prevent running the pump dry, which can degrade seals and lead to leaks.

- Understanding the diverse setup requirements of customers is vital, allowing our team to recommend the most suitable pump and accessories for the job.

Future Considerations:

Our commitment extends beyond the present success. Future endeavors include improving engine performance for reduced environmental impact and refining pump impeller and casing designs to eliminate stress points, minimizing the risk of pump cracking under high pressure.

Conclusion:

This case study not only highlights the transformative impact of our water transfer pump in rural landscapes but also underscores the importance of customer-centric solutions and ongoing innovation. As we, at Thornado, forge ahead, your insights contribute not just to our success but to the collective knowledge of industries facing water transfer challenges. Together, we shape a future where efficient water transfer is accessible to all, even in the most remote areas.