Imagine a situation where an outbreak of fire occurs, and the only hope you can ever get to defend yourself is a fire-fighting pump petrol. In such critical moments, reliability is not just desirable; it’s crucial. Whether it’s safeguarding a residential property, an industrial site, or a vast expanse of forest, fire fighting pumps petrol serve as the frontline protectors. But how can we ensure these pumps are always ready to perform when called upon?

Fire Fighting Pumps Petrol – The Backbone of Fire Safety:

To fight fires effectively, fire fighting pumps petrol are an essential part of the equipment. They are versatile and portable to draw water from a variety of sources to put out flames in a jiffy. Nonetheless, like any other mechanical apparatus, they need regular inspections and tests to remain reliable and effective.

The Role of Testing and Inspection in Fire Pump Maintenance

Similarly, regular testing is significant for the dependability of fire fighting pumps petrol. This process entails running the pump under simulated operating conditions to check its operational abilities and general performance. It helps identify any irregularities like reduced water pressure or engine malfunction that would necessitate immediate repairs or replacements.

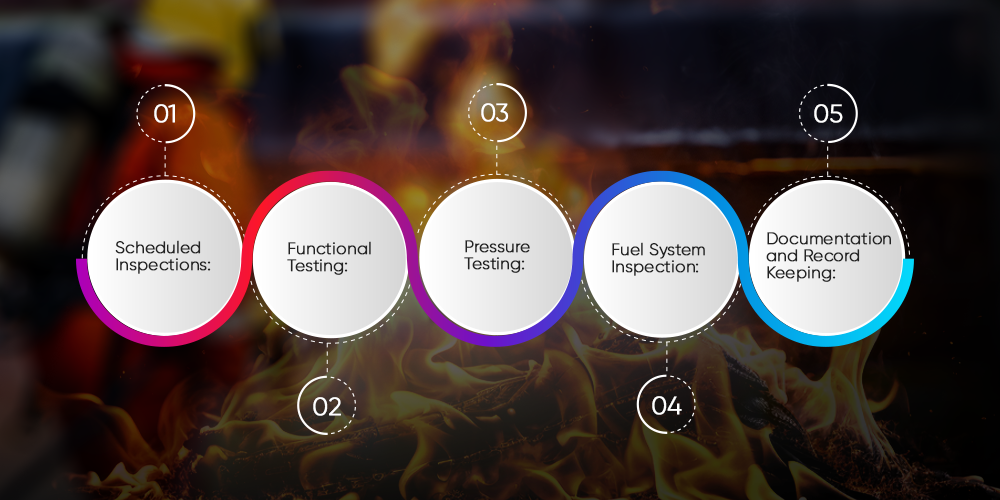

Scheduled Inspections:

However, inspections should be conducted at least once every quarter but depending on how often it has been used and where it has operated from, more frequent checks may be necessary

Functional Testing:

Do not fail to perform routine functional tests on your pump to ascertain if it functions as required. This includes both engine performance testing as well as pump performance testing.

Pressure Testing:

Perform pressure testing to verify the integrity of the pump system and hoses. Inspect hoses for signs of bulging, cracking, or other damage that may indicate weakness or imminent failure.

Fuel System Inspection:

Regularly inspect the fuel system for leaks, blockages, and contamination.

Documentation and Record-Keeping:

Keep detailed records of all inspections, tests, and maintenance activities performed on the firefighting pump.

Product Spotlight: Thornado Petrol 1.5 Inch High-Pressure Fire Fighting Pump Twin Impeller 7hp

One fine product among petrol fire fighting pumps is Thornado Petrol 1.5 Inch High-Pressure Fire Fighting Pump Twin Impeller 7hp. Definitely, this powerful pump boasts of having a suction inlet of 1.5 inches and three discharge outlets, making it to be versatile and efficient in water distribution. It has a maximum water displacement rate of 12,000 litres per hour with its twin impeller design which makes it work perfectly even under the most difficult circumstances.

Conclusion

Reliability is not something that can be compromised when dealing with safety from fires. However, regular inspections and testing are essential towards ensuring that a firefighting pump works well. We supply high-quality firefighting pumps, such as that mentioned above, for customers like you who might want to experience immediate results of their initial purchase investment in THORNADO products and services.

To get the best fire fighting pumps petrol as well as other comprehensive fire safety solutions click on THORNADO’s website today!